Specifications

Specifications

- Flat Products

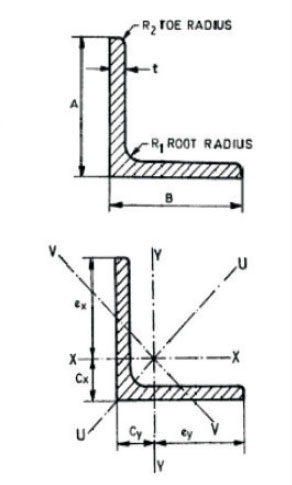

- Angles

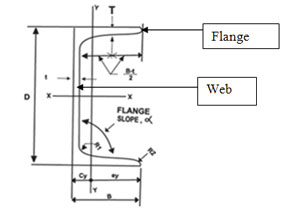

- Channels

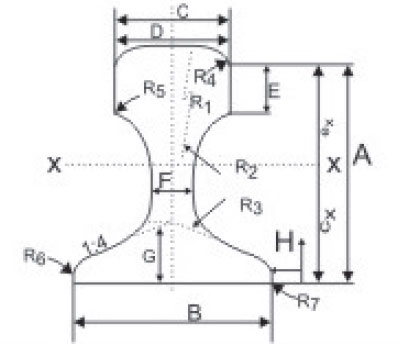

- Beams

- Rounds

- TMT

- Flats

- Universal Beams/Wpb/Npb

- Universal Columns

- H-Beams

- Squares

- Rails

- Crane Rails

- Pipes

Flat Products

Specifications: AS PER IS 2062 GRADE A/B E250/350/350HI/400/450/450HI, IS 1079 D

Color Sheets: PPGI/GL, GP Sheets/GC Sheets – IS 277

Grades

Sectional Properties as per

For Angles: IS : 808 - 1989

Tolerance as per

For Angles: IS : 1852 - 1985

Grades as per

For Angles: IS : 2062 : E250 A - 2006

Grades

Sectional Properties as per

For Channels: IS : 808 - 1989 / IS : 3954 - 1981

Tolerance as per

For Channels: IS : 1852 - 1985 / IS : 3954 - 1981

Grades as per

For Channels : IS : 2062 : E250 A - 2006

Grades

Sectional Properties as per

For Beams: DIN : 1025 – 1994 / IS :12778 – 1989 / IS : 808 – 1989

Tolerance as per

For Beams: DIN :1025 – 1994 / IS : 12779 -1989 / IS : 1852 – 1985

Grades as per

For Beams : IS : 2062 : E250 A – 2006

Rounds

| Specifications | Conforming to Grade |

|---|---|

| Structural | IS 2062 E250A – 2006/ SAE 1018 |

| Forging / Bright Bar Medium Carbon, High Mn Steel | 20C 15, 27C 15, SAE 1524S, SAE 1524CR CK-45, EN8, EN8A, EN8D, EN9,SAE 1049, 35C8 SAE 1524, EN15B, 37C15, A 105, 40Cr4 etc. |

| Spring Steel | 55Si7, 60Si7, 65Si7, SUP9, SUPl1 A, SUP10 |

| Case Hardening Steels | 20MnCr5, 16MnCr5 |

TMT

Specifications : Constructional

Conforming to Grade: IS : 1786 – 2008

| Standard | Grade | Remarks | Yield Srenght N/mm2 (min) | UTS N/mm2 (min) | % Elongation (min) |

|---|---|---|---|---|---|

| IS: 1786-1985 | FE- 415 | - | 415 | 485 | 14.5 |

| IS: 1786-1985 | FE- 500 | - | 500 | 545 | 12 |

| IS: 1786-1985 | FE- 550 | - | 550 | 585 | 8 |

| Re-Bars with Corrosion | CRM | Cu+Cr+P = 0.75 % min | 415 | 485 | 14.5 |

| Resistant Element | HSCRM | Cu+Cr+P = 0.75 % min | 500 | 545 | 12 |

| Earth Quake Resistance | EQR | - | - | - | 14.5 |

Reinforcement bars are used generally in construction projects.

Basically there are 3 Qualities in bars:

- CTD : Cold Twisted Deformed Bars

- TOR : Tor – 40

- TMT : Thermo-Mechanically Treated Bars

CTD & TOR-40 : CTD & TOR -40 are old forms of reinforcement bars but are now obsolete because CTD name itself suggests that it is "cold twisted deformed" bars. And it is twisted when it is cold, which leads to surface crack which makes the product more prone to corrosion. TMT Bars are much easily available and is of superior quality than CTD & TOR-40.

TMT Bars: Representation of TMT bars is done by its diameter.

For e.g.: 8mm TMT bar means diameter of that bar is 8mm.

Flats Specifications

MS Flats are generally used in Industrial gratings, various fabrication works & domestically, it is used in grills outside window.

Representation of M.S. Flats is done by the Width (W) & the Thickness (T) of the Flat. For example: When we say 25 X 5 FLAT, it means Width = 25mm & Thickness = 5mm.

Grades & Quality

There are no Primary producers of MS Flats only the Secondary producers i.e. Rolling Mills produces MS Flats. Various Rolling Mills follow the grades & quality specifications given in IS 2062. In general, MS Flats produced by the Secondary Manufacturers passes the physical parameters but fails to match the chemical properties of IS 2062 except few Rolling Mills.

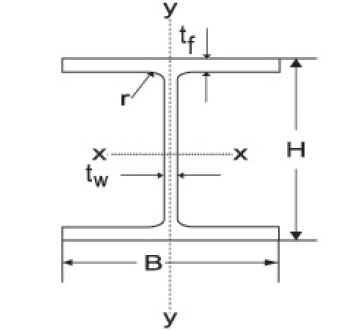

Grades

Sectional Properties as per

For Beams: DIN : 1025 – 1994 / IS : 12778 – 1989 / IS : 808 – 1989

Tolerance as per

For Beams: DIN :1025 – 1994 / IS : 12779 -1989 / IS : 1852 – 1985

Grades as per

For Beams : IS : 2062 : E250 A – 2006

Grades

Sectional Properties as per

For Universal columns: DIN : 1025 – 1994 / IS : 12778 – 1989 / IS : 808 – 1989

Tolerance as per

For Universal columns: DIN :1025 – 1994 / IS : 12779 -1989 / IS : 1852 – 1985

Grades as per

For Universal columns : IS : 2062 : E250 A – 2006

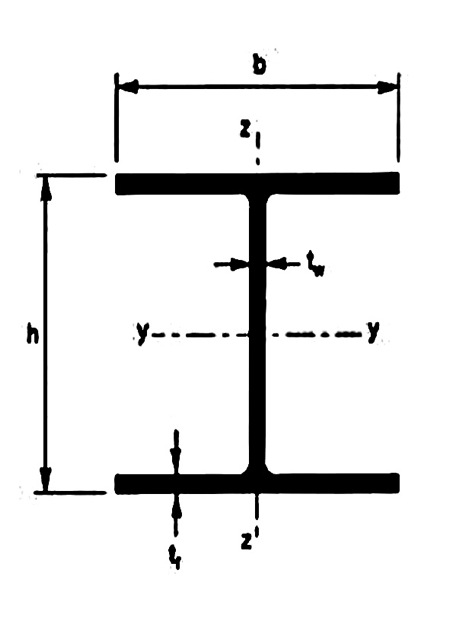

Grades

Sectional Properties as per

For Beams: DIN : 1025 – 1994 / IS : 12778 – 1989 / IS : 808 – 1989

Tolerance as per

For Beams: DIN :1025 – 1994 / IS : 12779 -1989 / IS : 1852 – 1985

Grades as per

For Beams : IS : 2062 : E250 A – 2006

squares

SAE 1018/ IS 2062/ IS 2830 for sizes above 65×65 mm. All the sizes smaller than 65×65 will be of MS grade

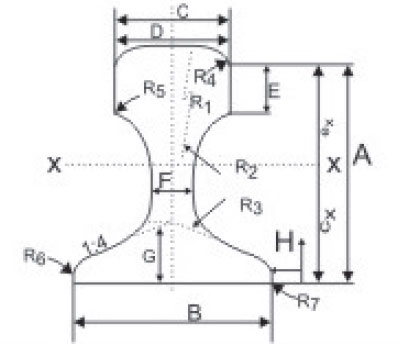

Grades

NO specs available as the rails are used ones.

Grades

As per IS: 3443 – 1980 Indian Specifications for Crane Rail Sections

Pipes

| # | Specifications | Description |

|---|---|---|

| 01 | IS: 1239(p-1)-2004 | Steel tubes for use for water. Gas. Air sterm. |

| 02 | IS: 3589-2001 | Steel tubes for water & sewage. |

| 03 | IS: 1161-1998 | Steel tubes for structural purpose & electric poles. |

| 04 | IS: 3601-1984 | Steel tubes for mechanical & general engineering purpose. |

| 05 | IS: 9295-1983 | Steel tubes used for idlers for belt conveyors. |

| 06 | IS: 4270-2001 | Steel tubes used for water wells plain end casing pipes. |

| 07 | IS: 3074-1979 | Steel tubes for use for automotive purpose. |

| 08 | IS: 4923-1997 | Steel tubes for use for hollow sections for structural use. |

| 09 | IS: 1978-1982 | Steel tubes for use in transportation of oil, gas & petroleum products. |

| 10 | IS: 1387-1985 | British standards for screwed & socketed & plain end steel pipes. |

| 11 | ASTM a 106 gr.b | Seamless tubes & pipes |

| 12 | BS 3059 | Boiler tubes |

| 13 | BS:EN-6323(p-1)1982 | Steel tubes for automobiles, mechanical & general engineering purpose. |

| 14 | ASTM-AS3, Grade-A | An american standard for steel pipes, black & hot dipped zinc coated and electric resistance welded pipes. |

| 15 | API 5L-2008 | American standards for steel tubes for use in transportation of oil gas & petroleum products |